Project Overview

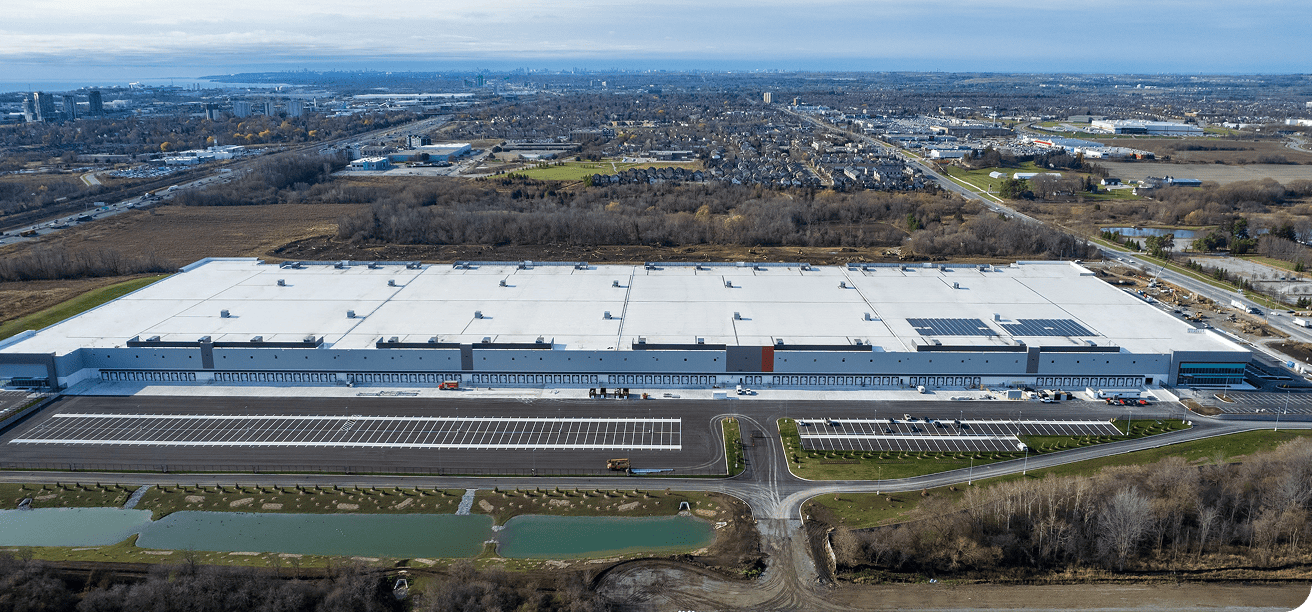

Lakeridge Logistics Centre (LLC) is a landmark industrial development redefining what’s possible in large-scale sustainable design. Spanning over 1.2 million square feet, this state-of-the-art logistics hub in Ajax, Ontario, combines cutting-edge building systems with exceptional environmental performance.

Engineered by INVIRO, the facility integrates advanced mechanical and electrical design, renewable energy strategies, and carbon-conscious materials — earning Zero Carbon Building-Design™ certification and targeting LEED® Gold. With its bold scale and technical ambition, LLC exemplifies the next generation of high-performance industrial real estate in Canada.

Need guidance on Zero Carbon or LEED® certification?

Talk to our team about how INVIRO can help you build better.

Pure Industrial

1,200,000 ft²

Zero Carbon Building-Design™ (ZCB-Design certified)

Targeting LEED® Gold

SABMag Award Winner

As one of the largest industrial projects to achieve this certification, LLC sets a strong precedent for how industrial developments can reduce emissions while enhancing asset value, improving operational efficiency, and supporting Canada’s transition to a net-zero economy.”

Sustainability Features

From advanced HVAC and LED lighting to rooftop solar and energy recovery, every system is engineered for efficiency and sustainability

High-performance envelope with continuous insulation

Electric air-source heat pumps and ERVs for heating/cooling

LED lighting systems with occupancy sensors and BAS integration

Destratification fans to reduce thermal stratification and improve comfort

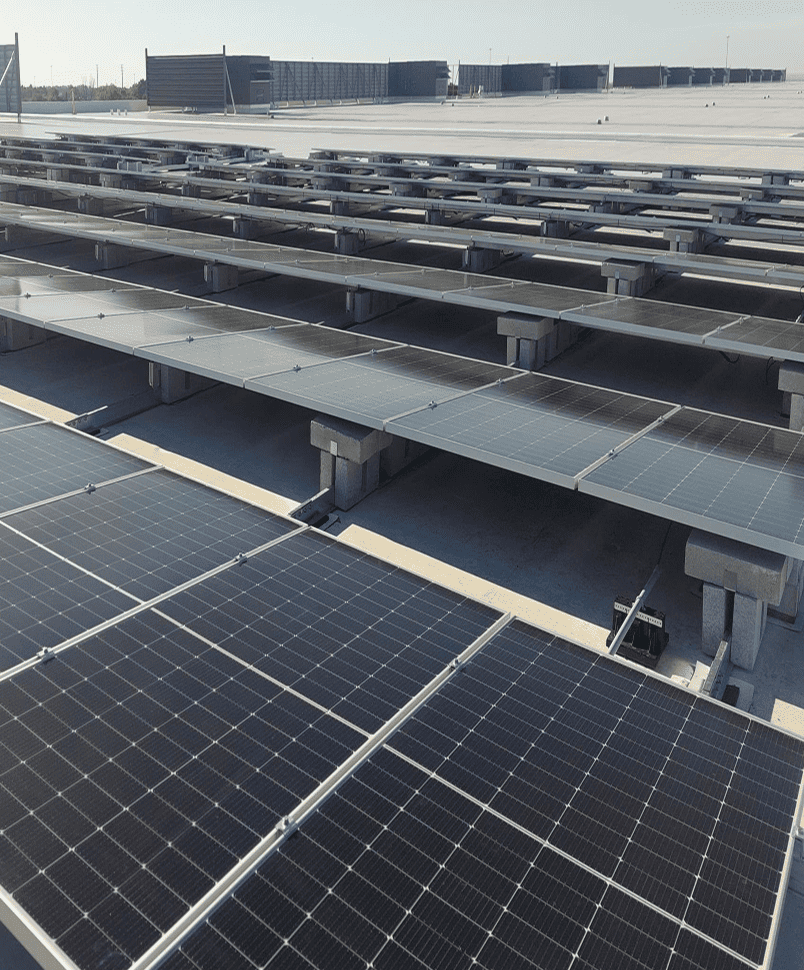

5% on-site renewable energy from rooftop solar PV

26% annual energy use reduction

CO₂ reduction: ~53,500 kg/year

Project Highlights

A quick look at key technical features that define the scale, function, and sustainability performance of the Lakeridge Logistics Centre.

Building type

Class A industrial warehouse designed to support high-volume logistics operations with optimized building performance and energy efficiency.

Size

1.2 million square feet of total floor area, engineered for flexibility, throughout, and future growth across diverse warehousing and distribution needs.

Clear height

40-foot clear height enables high-stacking storage and efficient racking systems, maximizing cubic space and operational efficiency.

Loading access

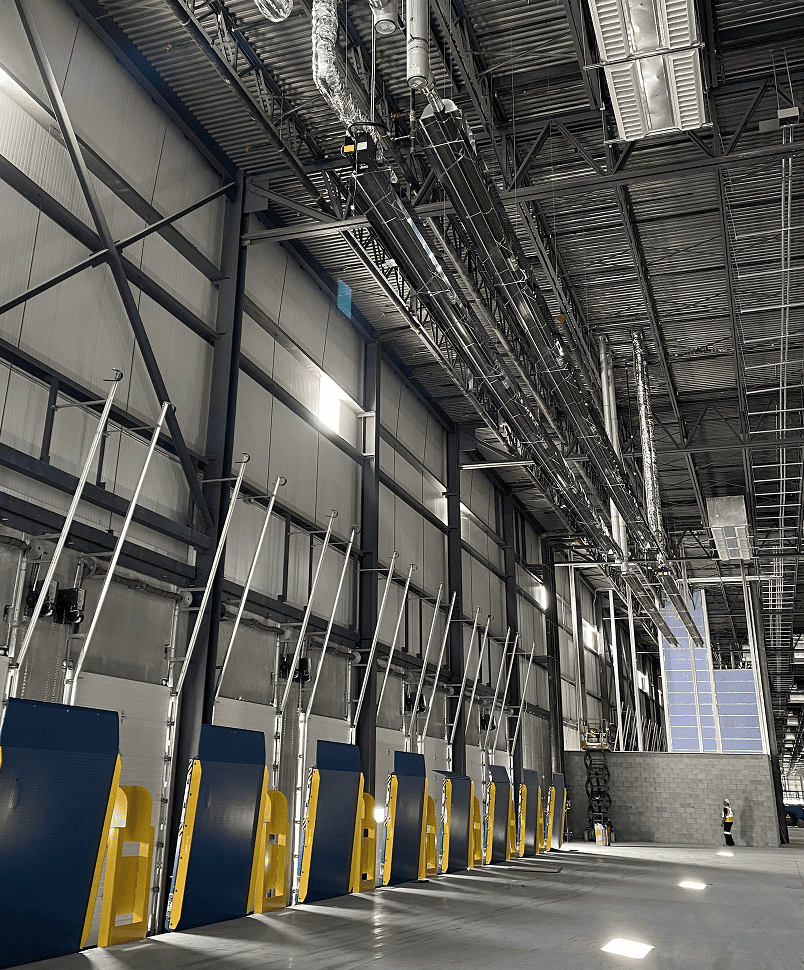

Equipped with over 200 truck-level loading doors to streamline logistics operations and accommodate high-frequency shipments and deliveries.

Parking

Features 250+ vehicle stalls designed for staff, visitors, and delivery fleets with efficient site circulation and safe access points.

Certifications

Zero Carbon Building-Design™ Certified by CaGBC and targeting LEED® Gold, showcasing its commitment to energy performance and environmental leadership.

Operational carbon

The building is designed with sustainability at its core, featuring a high-performance envelope with continuous insulation, a highly insulated roof and is paired with vertical dock leveling technology to minimizes infiltration loss.

The ultra-efficient mechanical system includes energy recovery ventilators and electric air-source heat pumps, which ensure optimal ventilation and air conditioning for the warehouse. Supplementary heating in the loading bay areas helps maintain temperature and reduce heat loss at the loading dock doors. Destratification fans are strategically placed throughout the warehouse to redistribute heat from the ceiling to the ground level, enhancing comfort.

The warehouse is illuminated with highbay LED fixtures equipped with occupancy sensors. These systems are managed by a centralized building automation system to ensure efficient operation.

Together, these design solutions contribute to a 26% reduction in annual energy use, saving 53,500 kilograms of carbon emissions each year. The project will offset 5% of its energy use with on-site rooftop solar PV, with the opportunity of future expansion with a solar ready roof and strategically sized electrical room.

Embodied Carbon Strategies

Reducing emissions from materials was a key priority in this project. The design team applied several carbon-smart strategies to minimize the building’s embodied carbon.

Reduced concrete usage

Low-carbon concrete mixes

Low-GWP insulation

Project Team

Bringing together experts across engineering, architecture, and planning to deliver a high-performance, sustainable facility.

Owner

Project manager

Zero carbon consultant

Architect

Mechanical engineer

Electrical engineer

Civil engineer

Structural engineer

Landscape architect

Urban planner

LEED consultant

Start a Smarter Project With INVIRO